What is a rain screen ?

What is a rain screen

What is a rain screen ? Simply a better way to build an exterior wall. It's a system that creates proper ventilation, which in turn gets rid of mold buildup. The term rain screen seems a bit of a misnomer because this type of wall cladding system does much more than prevent water from entering a building.

A rain screen wall controls condensation, allows for upgraded insulation to improve the walls heating and cooling properties and seals the building from air infiltration while allowing the wall to breathe through membrane materials. And it allows walls to be built with less material when compared to traditional brick veneer construction.

There are four common conditions where rainscreens are likely to be installed. Each requires slightly different treatment in terms of attaching cladding.

- Metal stud wall

- Wood framed wall

- Brick veneer wall

- Concrete block wall or slab wall

Metal & Wood stud framed walls

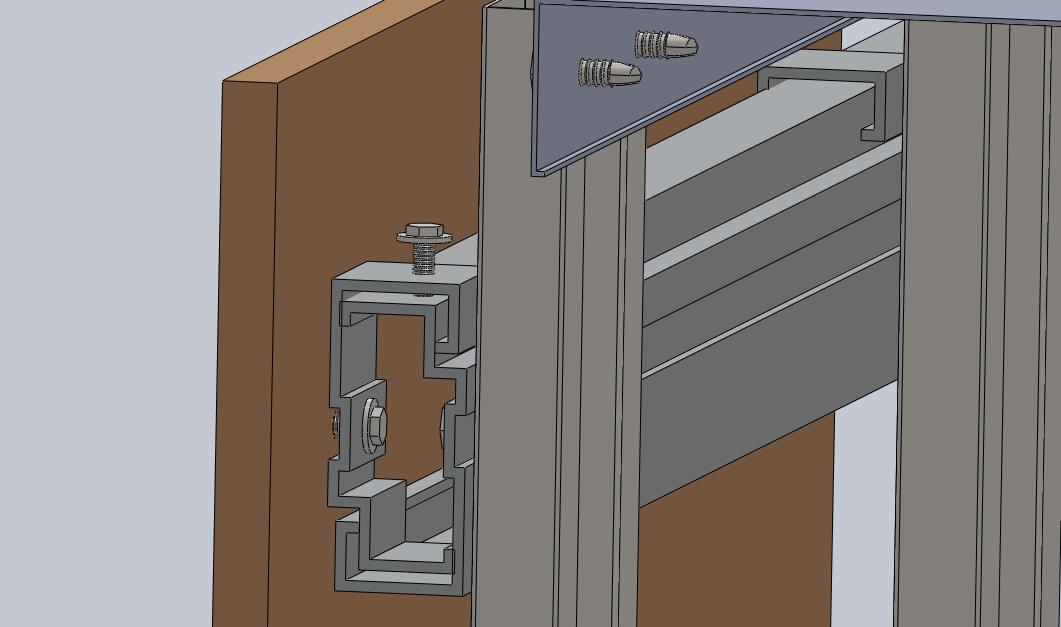

What is a rain screen girt system ? In a metal stud wall or a wood framed both will have exterior sheathing that will be the base on which the support girt system can be attached. Before the girts get attached there will some sort of breathable membrane which allows the wall to breathe.

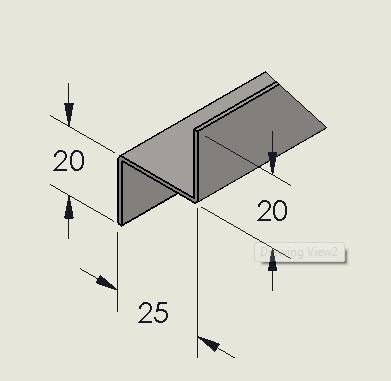

The steel or wood stud thickness and center to center spacing will have to be checked by an engineer to make sure it can carry the loads associated with the cladding. A system of horizontal galvanized steel Z girts is evenly spaced up the sheathing. The spacing is usually set to match the width dimension of batt or solid panel insulation that gets slipped into the cavities made by the girts.

The depth of the girts can be also varied to accommodate different thicknesses of insulation. In situations where spray foam insulation is used, the foam typically gets sprayed on in between the girts so that it does not expand beyond the girt line or depth of the girt.

Concrete block or slab walls

When cladding is installed over a brick veneer wall the spacing of fasteners becomes very important since they must land in the center of a brick in order for the loads to be carried safely. Fasteners cannot be attached to grout because of the danger that they will require much less force to pull out.

As well, old brick veneer in may need to checked or tested to see if the brick is still structurally capable of carrying load.

A concrete slab wall is much the same as a brick veneer wall in that no fasteners may be allowed to penetrate the grout. Fasteners should fall in the center of the block. The type of block must be rated to support the loads presented by the cladding. In a slab wall construction, the condition of the concrete is of great importance.

Similar to a brick wall, old concrete can degrade over time for a number of reasons. There must be assurances that it can carry the load of the cladding

Attaching Rainscreen Facade Panels

Facade panels can be attached to any of the above types of wall construction using similar construction methods. The method of attachment will vary since correct fasteners will have to be chosen to suit the substrate. Starting from the surface of the exterior wall there will usually be some type of vapour barrier installed such as Blueskin.

If additional insulation is desired, either in the form of spray foam or batt insulation, a horizontal galvanized steel zee subgirt can be installed. The Zee shape both holds the insulation batt in place and provides a mounting surface for the hatbars which support the panels. The Zees can be spaced horizontally at the width of the insulation batts. Zees can be installed with the outer leg down to facilate drainage of moisture.

Once the Zee and the insulation has been installed a weather barrier such as Air Outshield covers the assembly to keep rain out but still allow dampness from inside the system to vent.

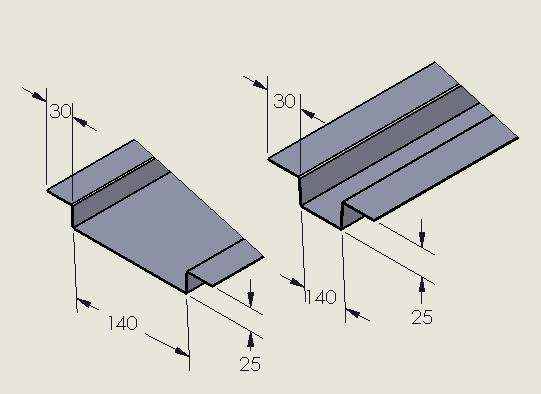

With the insulation protected, vertical galvanized steel hatbars or furring strips can now be installed for two purposes. The first is to provide support for the fasteners holding the facade panels at the desired spacing. The second purpose of the hatbar or furring strip is to provide a ventilated cavity crucial to the operation of the rear ventilated rainscreen system.

The ventilated cavity needs to be open at the top and the bottom of the hatbars or furring strips so that moisture can vent properly and wind load pressures can be equalized across all the panels.

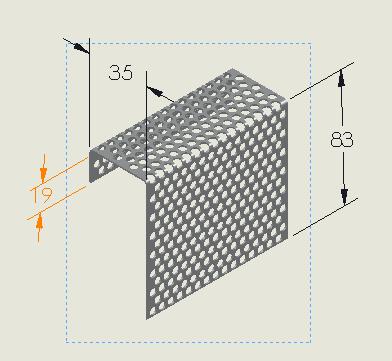

As well, what is a rain screen without vent screens to prevent bugs or birds getting into the ventilation cavity ?

This vent screen flashing is used at the top and the bottom. The vent screen shown below is a custom made black painted aluminum flashing designed to blend in with the facade system. Stainless steel wire screening is also used for this purpose.

Finally an EPDM gasket is used between the facade panel and the vertical hatbar to provide a weather seal as well as to assist in loading the panel fasteners so that the panel is held tightly but loose enough to allow movement due to thermal expansion or building movement.

EPDM is used because it is exposed to the sun between the joints of the panels. The block color gives the panels a consistent neat appearance at the joints

The galvanized steel components shown above are typically favoured in North American construction. Many of the manufacturers of high end facade panels are based in Europe and also use their own proprietary support systems. These systems are typically made of aluminum. These designs are more expensive to purchase than galvanized steel but can save labour time in setting up and aligning the panels.

The reason they are less expensive at the installation lies in the way they are designed to accommodate out of plane walls without shimming, as well as being able to be cut to length on site as opposed to galvanized steel which often needs to be cut to length in the shop. In the end the aluminum versus the galvanized steel system comes out the same in terms of total cost supply and install.

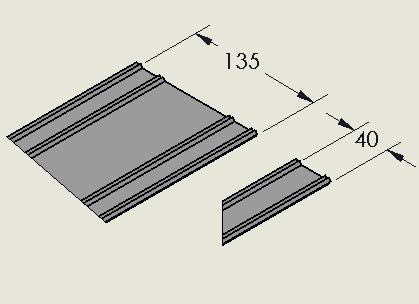

Other types of fastening system include this system for rear hanging by KEIL of Germany. This system still needs vertical galvanized hatbar or aluminum supports but substitutes the horizontal zees with custom aluminum extrusions. Clips for the fiber cement panel are made by cutting short pieces off the main extrusion and flipping them around so that hang off the horizontal support.

The clips are fastened to the panel using a small expandable fastener, designed specifically for the panel. Fasteners are available for most of the popular FC panels including Eter-Color, Swiss Pearl and more. Generally the panel must be 13mm or 1/2" thickness to provide sufficient material for the fastener to grab. The clips also have adjusting screws to level up the panels as they are installed.

Rear fastened systems give a very clean look to the installation but if insulation is required in the cavity behind the panel, some means will have to be thought to allow insulation batts to be easily installed. With systems that use zee bars, the downward pointing leg of the zee helps hold in the insulation batt.

What is a rain screen - Future developments.

Clip systems have been made that include include full thermally broken clips which effectively break the transmission of cold through the metal support system. An example of this is the T-Clip system used by Canadian manufacturer Engineered Assemblies