Dummy Leg drafting and development

Dummy Leg drawing and development

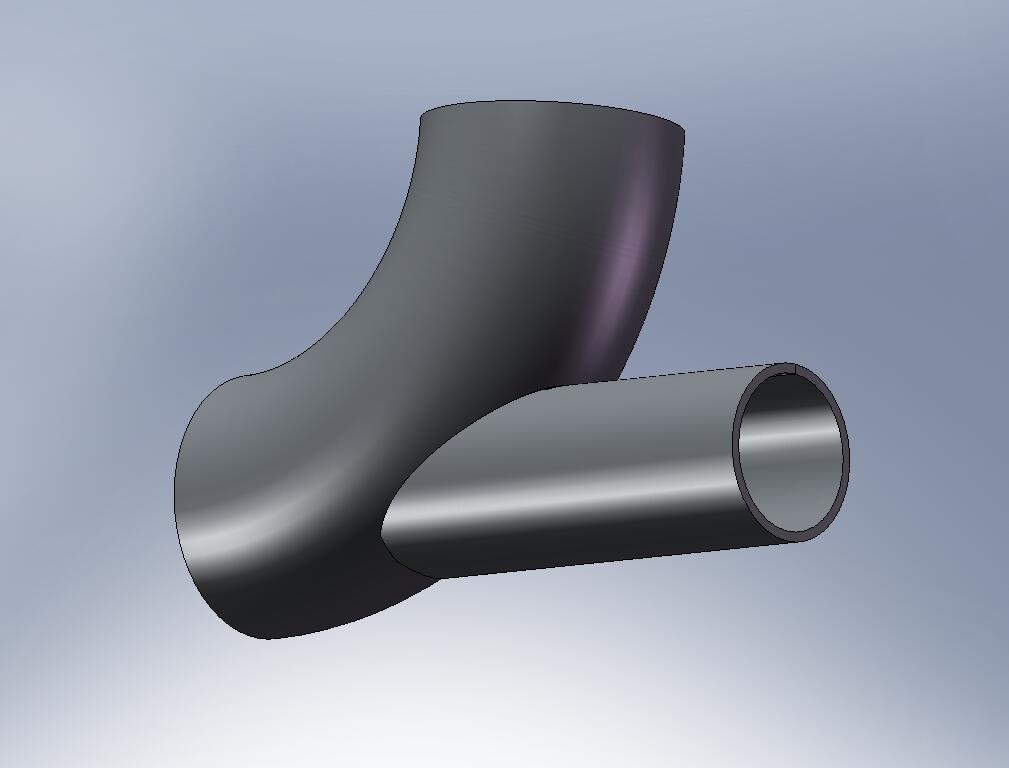

Dummy leg drafting and development is used in the piping industry. A dummy leg is a stand that is used to support a section of piping but it could also be a branch pipe added to an elbow, straight pipe or transition

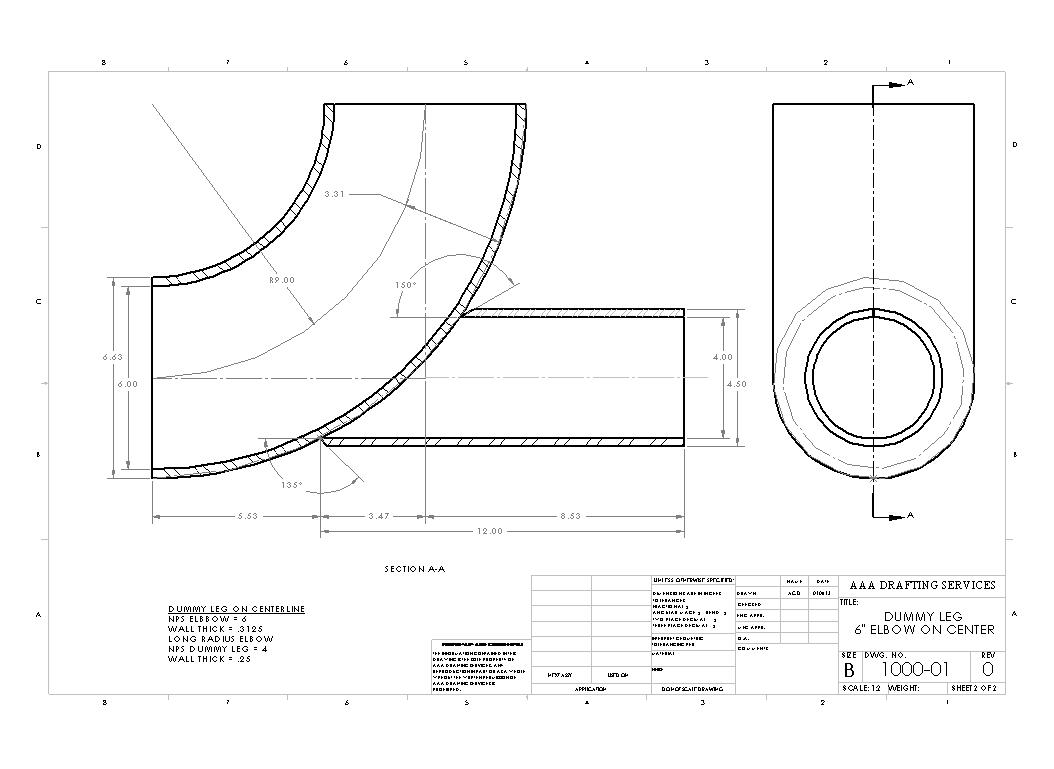

It gets a little tricky when you have to layout and weld one of these supports onto an elbow or other circular shaped pipe fitting. It also gets more difficult when the support has to be offset from the pipe centerline, perhaps because of building structural steel that might be getting in the way.

In the past, in order to figure out how to cut a stanchion or support pipe that intersected an elbow meant you to do parallel line development.

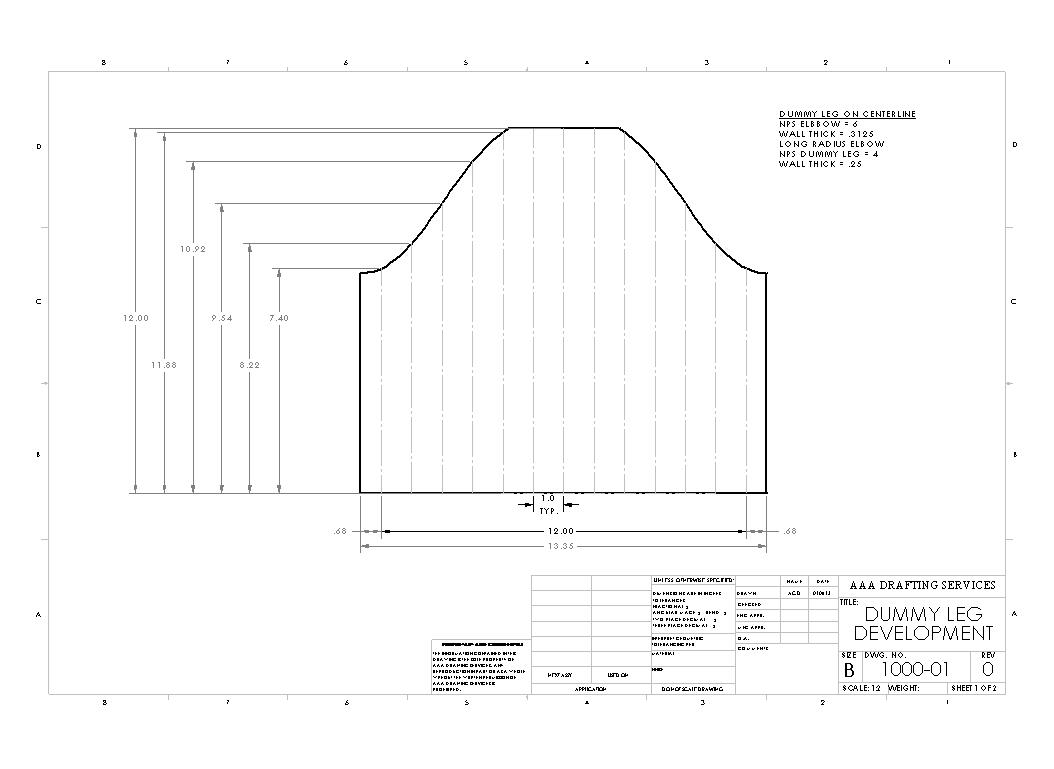

That meant hand drawing a section through the fitting where the stanchion intersected and then using your drafting machine to project horizontal and vertical guidelines onto a detail of the stanchion.

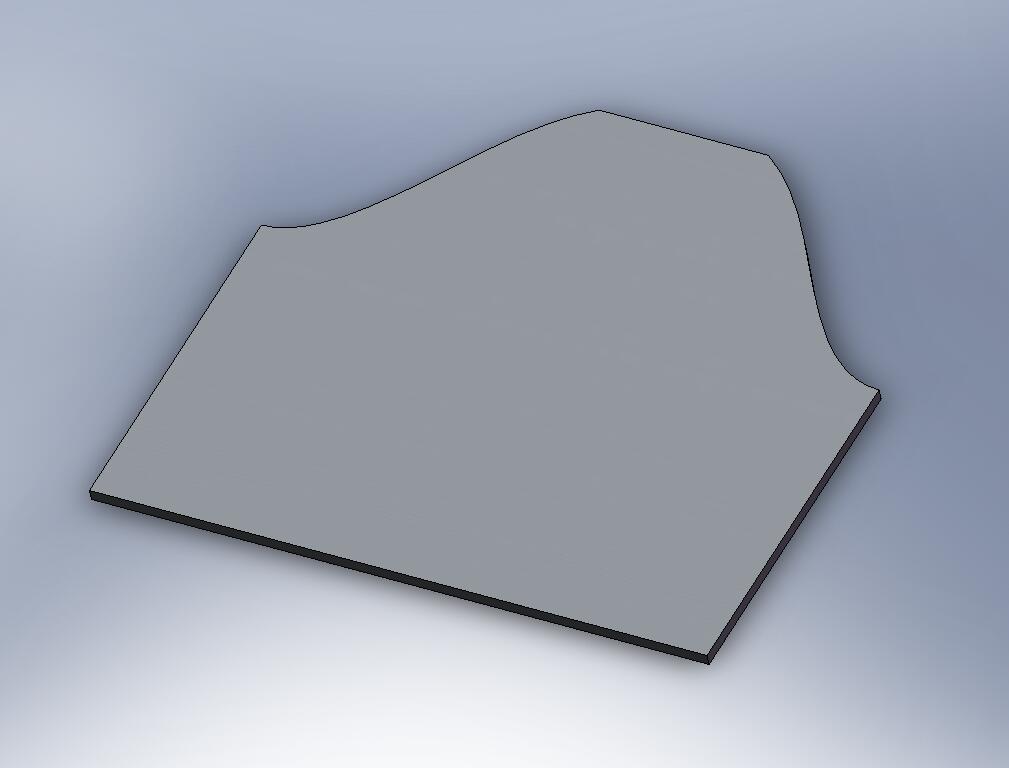

With a full size drawing made by parallel line development a welder/fitter can wrap the the drawing around the stanchion as a template and mark exactly where he or she has to torch cut or hand grind.

Download a sample pdf full size drawing here

Needless to say the development template has to be dead nuts otherwise the stanchion wont fit and is just becomes scrap. (The welder fitter will have some choice words for you too !)

3d drafting software makes things a little easier because once you have the conditions modeled you can just dial in the necessary pipe diameters and cut the elbow through the stanchion to get the profile just right.

After that is done, you can generate the flat development using the CAD software. The only thing that needs to be done after that is to add guidelines on the drawing to aid the welder / fitter in locating the drawing once he or she uses it as a template.

This kind of template creation is not limited to the piping industry. It can be used with brackets for traffic signals for example, where one support tube has to join to a lamp post or support at an angle.

Do you need pipe templates ?

If you are joining pipes and need full size pipe developments printed out for pipe cutting, I can generate them and have the drawing couriered to you at the job site. I need some basic information about what you are joining

- The main pipe or fitting you are joining to and its size and specifications

- The size and specs for the branch pipe you need to cut

- The angle the branch pipe meets with the main pipe

- The offset if the branch pipe does not pass through the centerline of the main pipe

Pipe development drawings are printed full size so they can be wrapped around the branch pipe for marking and layout of the pipe.

Contact me at 905-467-0233 if you need more information.