Railroad track maintenance

Railroad track maintenance is critically important worldwide to keep freight moving and to maintain safe operating conditions. I have worked on the repair of Railroad crossings, diamond crossings and turnouts and other metal railroad track components. All of which are under considerable stress due to the heavier axle loads of enormous locomotives and longer trains.

Eventually inserts, frogs and rail sections all have to be replaced. Often the drawings that engineering has to work with do not give enough information for the fabrication of the needed components. Many times you only have the old damaged track section to work with to create a new part

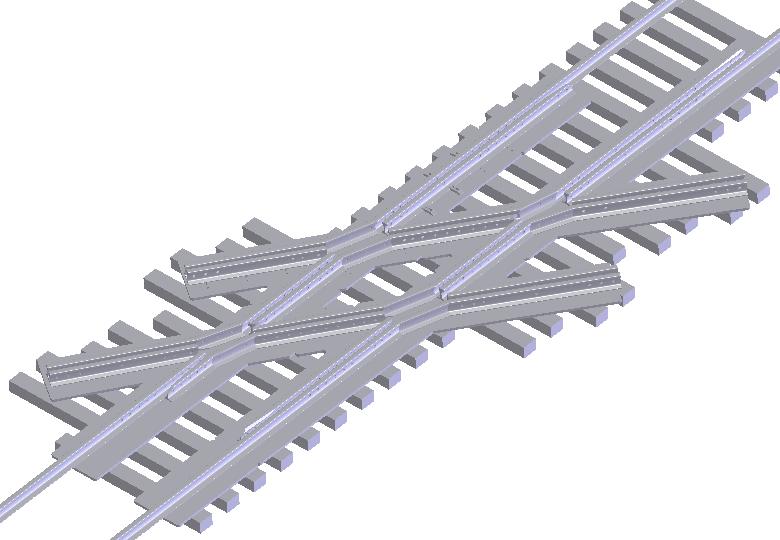

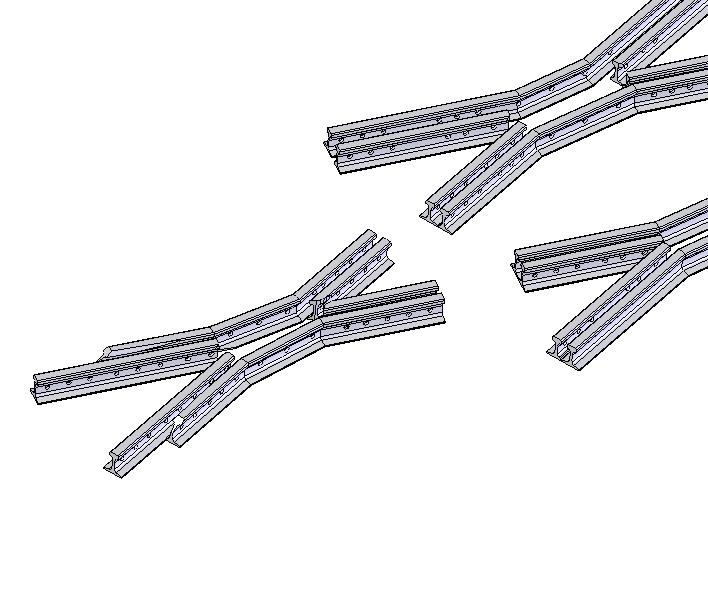

In the crossing below a 2 inch thick steel plate had to be designed to fit underneath the entire crossing to provide proper support.

Diamond crossing repair

The geometry of a diamond crossing looks simple enough until you try to calculate lengths of bent rails and bend angles. Once all of the bent rail angles below were calculated they were placed in a fixture and a custom made acetylene torch was used to heat the 136 pound per yard rails hot enough for bending.

In addition to trackwork I also get involved in shop drawings for the repair of rolling stock. The Control panel below comes from a Government of Ontario GO Bilevel commuter car

Commuter car repairs

I have also worked on Wabco disk brakes and suspension components from GO train cars as well as being involved with the mezzanine for the Bilevel car wash facility.

Rolling stock suspension components

If you have to make new train parts or track sections and need drawings to make it happen please give me a shout