Shipping Container door details

The following shipping container door details show some ways that doors and windows can be installed in a shipping container.

Before getting into the actual shipping container door details, we need to talk a little about building permits.

In industrial and commercial shipping container builds, and for most shipping container homes, you need a building permit. When you need a permit a professional engineer will have to sign off on the method used to install the windows and doors. Most of the time its the engineer who will dictate the framing method used because he or she is signing off and taking responsibility for the safety and structural integrity of the container.

With a shipping container any time you cut a hole in the corrugated steel sides you weaken the structure. Engineers will usually want to err on the side of safety and use hollow steel tube frames for the windows and doors welded in place to replace the steel removed to make the hole. Because there are no standards for shipping container home construction, Engineers will have differ in the ways they prefer to have window and door frames made.

There are some engineers who will sign off on riveted sheet metal window and door frames. Those types of frames are better in terms of creating a functional building envelope as well as adding structure back to the container. The challenge will be getting the engineer on side with this to the point they put their reputation on the line signing off on the drawing.

I will present shipping container door details here that look at maintaining a consistent wall thickness or depth so that all the drywall or interior finish is on the same plane regardless of the transition from windows to door. I am also thinking about building envelope issues like shedding water and sealing. Finally im looking at providing adequete mounting surfaces so windows and doors can set in place. First, lets discuss the pro's and con's of the welded frame method.

Welded rectangular tube door frames for shipping containers

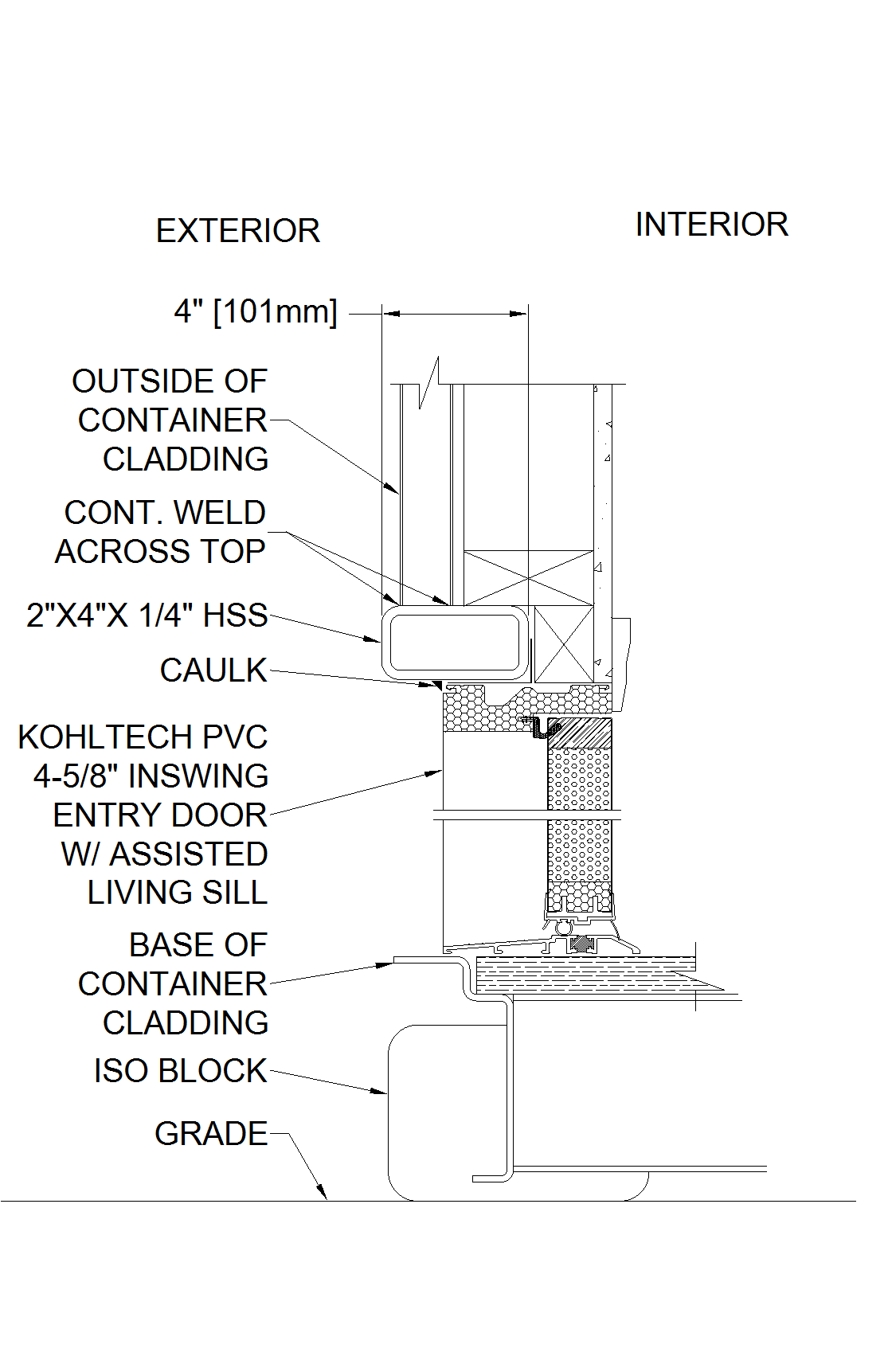

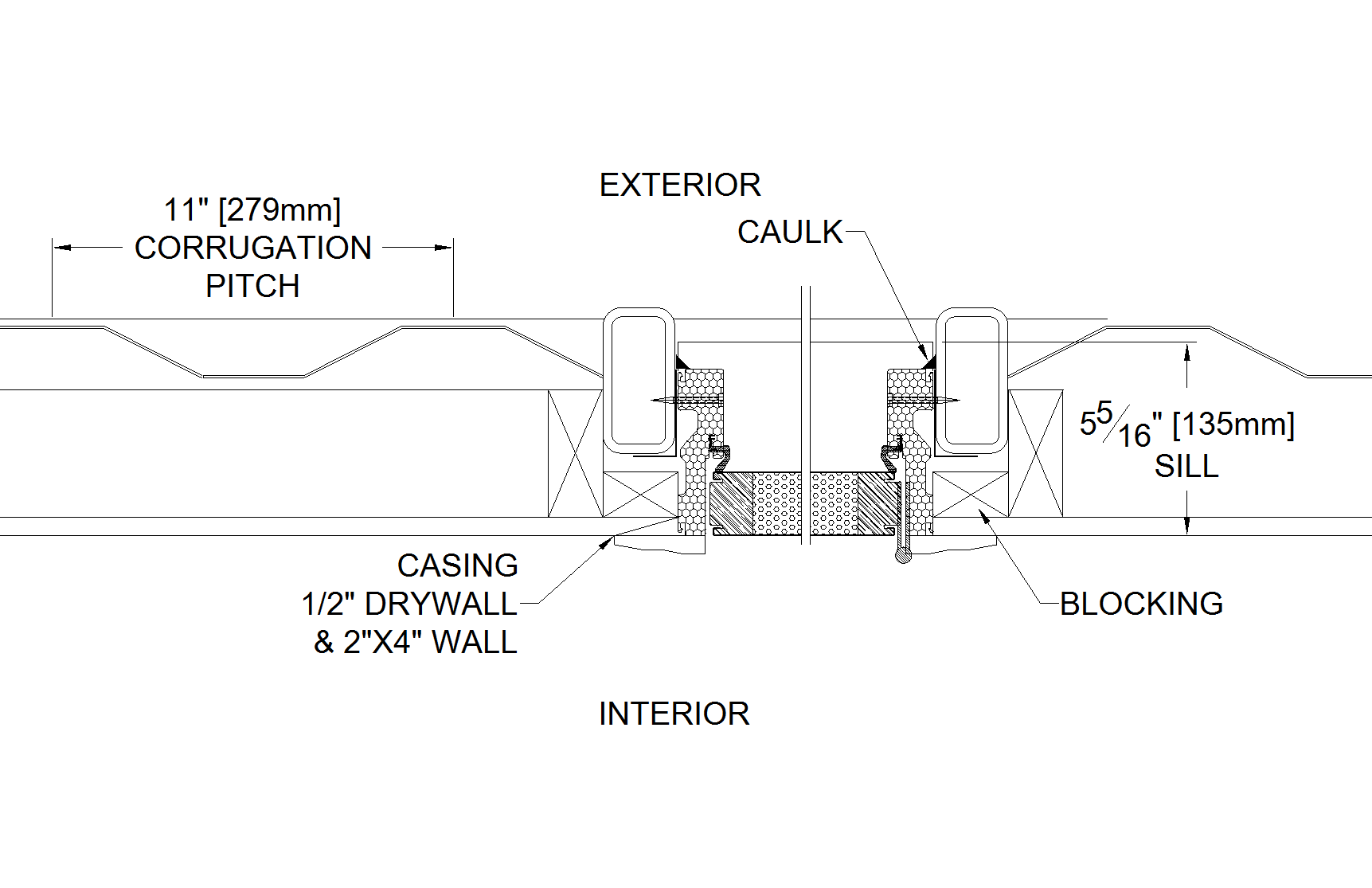

The picture below is a typical cross section through a residential shipping container home door. Non insulated shipping containers are made of corrugated panels of Cor-Ten steel welded together. The pitch of the corrugations is very close to 11 inches.(280mm). The pitch is a little wider in areas where there is a welded seam joining two panels. Because of the wavy corrugations you need a wide enough steel tube or flat plate so that theres room for a fillet weld on the outside. The tube has to be wide enough across the top of the door to weld all the way across.

Shipping Container door details - 1

You do not need a continuous weld for strength, its overkill, you need it to seal the frame against the weather. You can tack weld the frame all around and then fill the gaps inbetween the welds with caulk. But that looks awful and wont last more than a few years in the weather. Its nowhere near as good as a small continous weld bead especially at the top or header where all the rain and snow drips off the top of the door. The 2" x 4" x 1/4" HSS rectangular tube acts like a drip edge, keeping the water off the front of the door.

The door you choose makes a difference too. In this application I tried to used the most basic type of door. Most residential doors vinyl and wood have a casing depth of 4-5/8". That means if you are going to be framing your shipping container with 2x4 walls and drywall you want the door to be flush with the drywall on the inside so you can fit casing to the door just like a residential home. But at the same time most residential doors come with a 6-5/8" wide threshold. Thats too wide for a shipping container because it will hang over the edge. You want the edge further back so you can caulk it and seal it.

Shipping Container door details - 2

In the shipping container door details above you can see how I used an assisted living sill which is much narrower. Another advantage to this sill is that it has a flat transition to the container floor. Regular residential doors have a high sill on the inside where flooring is meant to be at a higher level than the outside concrete sill. That can result in a trip hazard in a Sea Can. In a shipping container its mostly flat from outside to inside.

By and large the biggest advantage of welded tube frames is that provided the container walls are flat, you can put door frames and window frames anywhere you like. The sizes of the frames are only limited by the door and window sizes you have at your disposal.

Problems with welded door and window frames in shipping containers

One problem with welding in a brand new container is that you have to grind off the paint and Zinc Chromate primer the container manufacturer uses to prevent rust. Even if you touch up the paint after welding its really hard to prevent rust coming back.

Another problem arises when you are using used containers. You cant always tell if there is a bow out or a bow in in the walls of the container. There may be big dents exactly where you want to put your door or window frame. These conditions can prevent your welded frame from going in straight and plumb.

The first thing to determine is the door width. 36" wide doors are very commonly used in industrial settings. But 30", 32" and 34" doors maybe selected due to cost & availiability. Steel doors can be ordered with frames, which is preferable because cutting hinge locations and lock holes into your own steel frames is difficult and time consuming without special equipment. A steel door with a single rabbet frame fits well in a shipping container.

Even if you order a 36" wide door with a rabbet frame you will still need to weld a 2" x 4" x 1/4" rectangular tube HSS frame into the shipping container so you have some where to screw the rabbet frame into. The 2" x 4" HSS allows you to locate the door anywhere along the sides and back of the shipping container without worrying about the pitch of the corrugations. No matter what location, the cut corrugated steel edge will allows land perpendicular to a flat part of the 2" x 4" HSS, making a perfect location for a strong weld all around the frame.

For door installation, we are assuing here that the install is being done on a new container. Used containers can have badly dented walls. That will dictate where you can put your door or window frame. Its fine if you will be cutting out the material around the dent but if you have a large long dent thats located right where you will be putting your frame you need to relocate the door or window to someplace where the walls are perfectly flat.

Here is an example of a 36" rabbet frame door being installed in this way. Notice the lengths they go to to keep the frame square, using a temporary cross brace at the bottom and the use of temporary support pads to trace the outline of the frame for cutting the container opening.